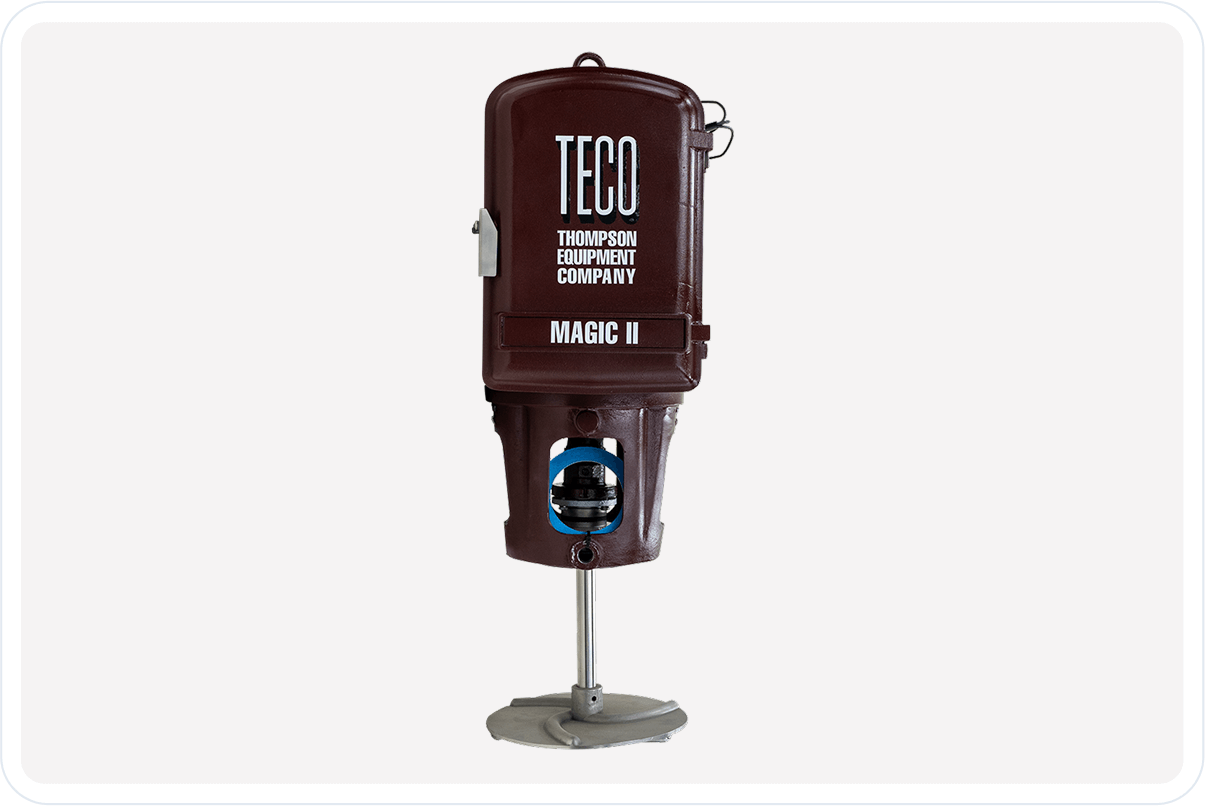

TECO MAGIC II

TECO’s Magic II is a loop powered SMART + HART rotating disc shear force consistency transmitter. The transmitter measures consistency by sensing the change in viscosity with a disk rotating in the paper stock.

Product Summary

Download Product Summary SheetTECO’s Magic II is a loop powered SMART + HART consistency transmitter. The transmitter measures consistency by sensing the change in torque with a disk rotating in the paper stock. A non-contact electronic system eliminates accuracy issues brought on by friction and drifting problems that may be by wear and corrosion.

Magic II’s SMART feature has ten available response curves to match the nonlinear pulp response curves. This gives higher accuracy than traditional nonlinear response curves because it adjusts for higher sensitivity at low consistency and lower sensitivity at higher consistency.

Magic II’s HART feature uses digitally set upper and lower range values. With a HART compatible device, you can program or read the loop’s current output and consistency value anywhere the 4mA to 20mA wires run; from the control room to the transmitter.

The Magic technology is more responsive to rapid changes in consistency. This enables the controller to “see” process upsets and hold consistency closer to set point. By reducing consistency variations in the feed stock to the Paper Machine, paper quality will be improved while using less fiber.

Features & Benefits

- Non-Contact Torque Torque Measurement

- No drift.

- No damage to electronics.

- HART Compatible

- Bi-directional communication enhances diagnostics

and configuration and provides quick visibility into

the device. - Early warnings and problem detection minimizes

impact of deviations and prevents costly shutdowns.

- Bi-directional communication enhances diagnostics

- SMART motor driven consistency transmitter

- High sensitivity to consistency changes ensures

accurate and responsive measurements. - Insensitive to variations in fiber length.

- Velocity immunity eliminates the need for velocity

compensation or increasing pipe size.

- High sensitivity to consistency changes ensures

- Loop Powered 24 volts

- Simplified wiring requires only one pair of wires for

both power and output. - Transmission that outperforms voltage signals over

long distances and noisy environments.

- Simplified wiring requires only one pair of wires for

Applications

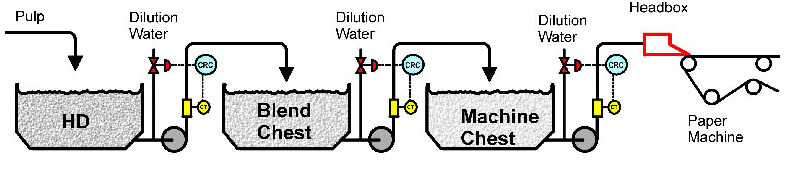

Profitability and Product Uniformity via the Consistency Control Chain

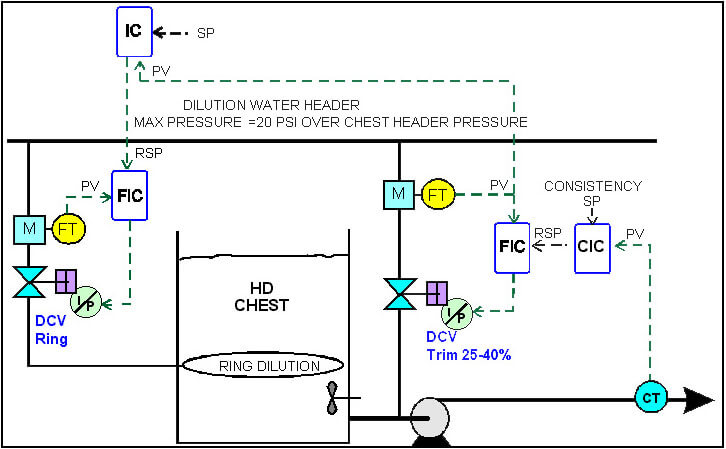

Tight basis weight profiles optimize material usage, product uniformity and profitability. Consistency deviations from the Hi-density tower are reflected in basis weight variations. Tightening the basis weight profiles requires minimizing these consistency deviations.

Each transmitter in the “Consistency Control Chain” reduces consistency variation. The cumulative effect of ALL the transmitters working together determines basis weight profile. Contact TECO for a FREE evaluation of your “Consistency Control Chain”. TECO can provide you with consistency solutions you can add right to your bottom line.

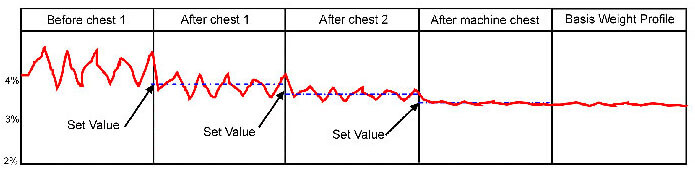

Flow Controlled Dilution, Trim Dilution Only

Flow control is a much better method of controlling dilution water than valve position. It will give tighter consistency control.

WHY?

Changes is dilution header pressure and chest level, effect the amount of water passing through the control valve. Flow control responds faster to pressure changes. Contact us if you want additional information on flow control and how to set up flow control for a HD chest.

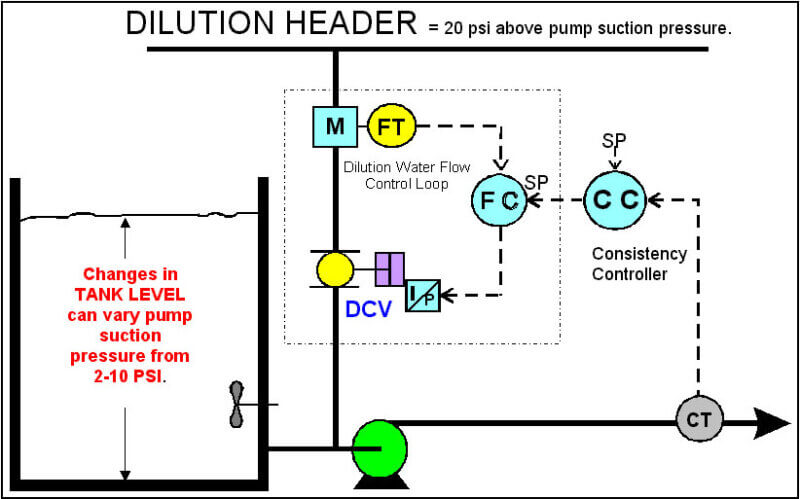

Flow Controlled Dilution, Ring and Trim Dilution

- RSP = Remote Set Point

- SP = Set Point

- IC = This controller has a dead band that keeps DCV Trim valve in its optimum control range.

- CT = Consistency Transmitter

- PV = Process Variable

Consistency Control Chain Evaluation Procedure

Purpose: To identify any equipment or control strategies that would contribute to poor consistency control.

TEST TO BE PERFORMED

1. Manual Bump Test

- Place system in manual control

- Change dilution control valve position by 10 %.

- Return valve to original position

- Put system back in automatic control

- Note Time to Meter Response =Dead Time.

- Note rate of change and time needed to stabilize.

- Note time and rate when valve is returned to original position.

2. Set Point Change (Loop is in Automatic Control)

- Change setpoint by at least 0.2 % consistency

- Return to original setpoint

- Note time to first response = Dead Time

- Time of stabilizing period.

- Rate of change to stabilize.

- Return to original setting.

3. Control Loop Information

- Average Consistency deviation from setpoint ( 2 min. minimum time frame)

- Gain and Reset for each loop

- Dilution Water Header Pressure

- Dilution Control Valve Type and size

- How was size determined

- Injection point and style

4. Sampling Procedures

- How often are samples taken

- By whom

- Test Method

- Sample Valve location & Type of valve

- How are sample results used

Specifications

| Sensitivity | @ 2.5 % consistency as ± 0.003%; @ 4.0 % consistency as ± 0.002% |

|---|---|

| Consistency | Range adjustments made in % consistency from any HART Protocol adjustment device such as a MeriamTM, RosemountTM (375,475), SMARTM or Emerson AMS Trex Communicator. |

| Pulp Curves | Furnish-specific calibration curve, 0.5 to 7.0% installed in transmitter, additional curves available |

| Torque Sensing | Non-Contact Inductive coupling with Stationery Proximity Sensor; approximately .030 in Air Gap |

| Power | 2-wire, 24-30 volts DC, minimum 250 ohm loop resistance |

| Sensing Motor | Standard 440 vac 3 phase 1/2 hp @ 1 amp. Optional 575 vac motor is available |

| Output Signal | Liner 4-20mA into 350 ohm max. load @ 24 volts,1300 ohms @ 30 volts |

| Output Dampening | Silicon oil dampener plus digital electronic filtering, 1.5 to 100 seconds (1.5 sec. factory setting) |

| Output Test Points | 4mA and 20mA |