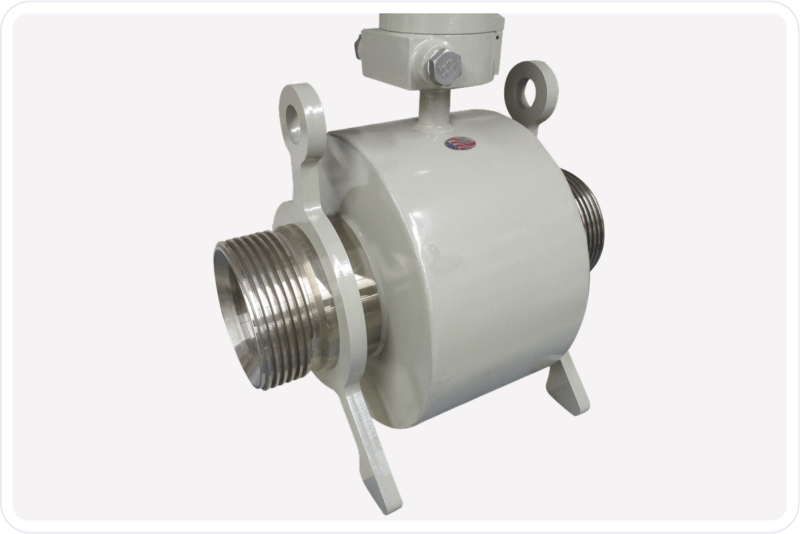

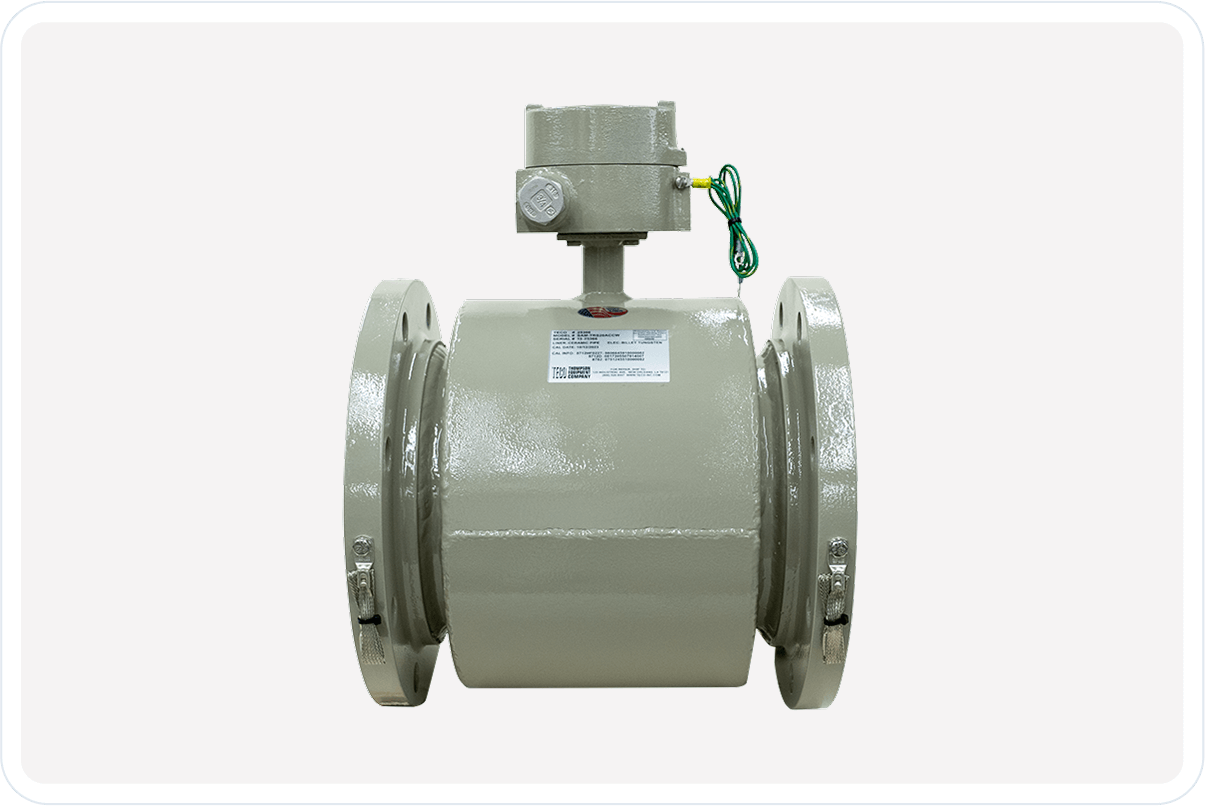

TECO Severe Application Meter (SAM)

A magnetic flow meter with abrasion resistant ceramic trim that exceeds the capabilities of Alumina or Yttria Zirconia. Capable of withstanding a variety of corrosive slurries, acids, bases and solvents.

Product Summary

Download Product Summary SheetSevere application magnetic flowmeters with erosion and abrasion resistant designs capable of withstanding a variety of highly erosive applications and corrosive slurries. Magmeters with liners made from specialty materials like magnesia stabilized zirconia ceramic, aluminum oxide ceramic, polyurethane rubber, neoprene rubber, Linatex, teflon, rotationally molded tefzel, and others; custom electrodes made of a variety of metallurgical choices, including stainless steel, tungsten carbide, platinum, and hastelloy.

Applications

Measurement of extremely abrasive slurries in Mining, Pulp & Paper, Fracking, and Oil and Gas Exploration (will not measure oil or gas).

Flow Measurement of Extremely Abrasive Slurries

Proven in the heat of a West Texas summer, and the cold of an Alberta winter, this TECO magmeter is designed from the ground up to withstand corrosive slurries, acids, bases and solvents.

Uptime and operational efficiency are critical to oil and gas operators. Billing rates can rise upwards of $20,000 per hour. Failure of process equipment causes long delays in fracking progress and decimates equipment budgets. Magnetic flow meters (magmeters) installed on blenders are of particular concern. The application involves accurately measuring the flow of an extremely erosive slurry comprised of sand and frack water (a mixture of water and chemicals). Replacing failed magmeters can take up to 4 hours, and requires the shutting down of the entire frack spread.

Calling upon sixty-plus years experience in magmeter application, failure analysis, repair, and design, TECO developed several innovative features to extend longevity in fracking operations. First, TECO developed a ceramic sleeved liner made of “magnesia partially stabilized zirconia”, a very tough ceramic used in severe-service applications that provides corrosion resistance and durability.

Second, TECO developed electrodes built from a solid tungsten carbide billet, which afford unparalleled wear resistance. Given the sand density in the frack fluid, noise reduction is critically important; so, the tungsten carbide is polished leaving a hard, smooth finish that significantly reduces noise in the electrode circuit.

Finally, TECO designed the meter as a drop-in replacement. It operates with a variety of secondaries and matches the lay length of the meter being replaced. There is no need for a new transmitter or repiping, allowing for simple retrofit of existing installations.

In 2017 TECO introduced the SAM (Severe Application Meter) magmeter as a flow meter designed specifically for hydraulic fracturing operations. By specifying SAM, operators have saved money through increased uptime; decreased health, safety and environmental risk; and reduced costs related to magmeter purchase and repair.

Specifications

Download Spec Sheet| Sizes | 1/2" - 40" |

|---|---|

| Flanges | ANSI/ASME Cl 150/300, AWWA, Other available upon request |

| Lining | PTFE, Tefzel, PFA, Neoprene, Polyurethane, Hard Rubber, Ceramic, Ceramic Brick, others available upon request |

| Electrodes | 316SS, Hastelloy B-3, Hastelloy C-4, Tantalum, Platinum, Tungsten Carbide coated Hastelloy B-3, Conductive Low Noise, Billet Tungsten Carbide |

| Accuracy (with DC Signal Converter) | 1/2% of rate (1 – 10 M/sec scale) |

| Accuracy (with AC Signal Converter) | 1% of rate (1 – 10 M/sec scale) |

| Pressure Rating | 285 psi at temperatures up to 100°F |

| Temperature Rating | 400°F at pressure up to 200 psi |

| Max Temperature Gadient | (estimate 100° per min.) |

| Wetted Materials | Tungsten Carbide Electrodes; Lining – Magnesia partially stabilized Zirconia (MgPSZ) |

| Environment: Temperature | 0°F to 140°F |

| Environment: Submergence | IP68 / NEMA 6P |

| Environment: Exterior | Epoxy Paint |